How does the pre-laid reverse-bonding method eliminate water leakage channels beneath polymer self-adhesive membrane waterproofing?

Release Time : 2025-09-10

At the forefront of modern underground engineering and building waterproofing, polymer self-adhesive film pre-laid waterproof membrane, acting as an "invisible guardian," quietly builds a watertight foundation for buildings. It's more than a simple replacement for traditional asphalt membrane; it's a high-tech waterproof barrier that integrates polymer material science, bonding technology, and construction revolutions. With every concrete pour and chemical bond formation, it transforms passive protection into active integration.

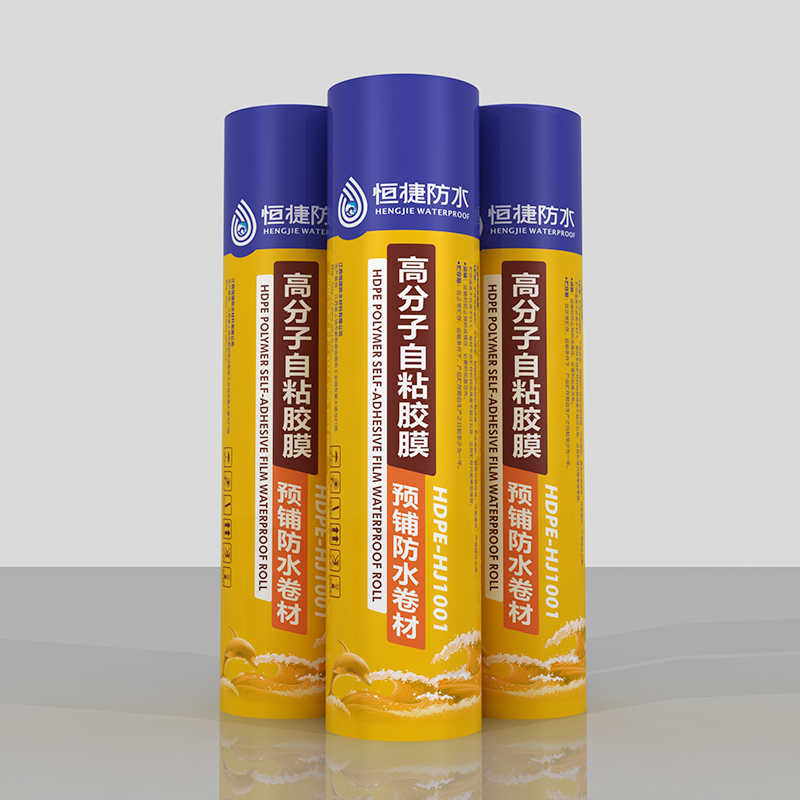

Upon first encounter with polymer self-adhesive film pre-laid waterproof membrane, its beauty stems from a "symbiosis of purity and precision." The membrane's surface is smooth and polished, exhibiting the characteristic uniform texture of polymer materials. Its color is pure, typically translucent or light, and it lacks the black stains and pungent odor often associated with asphalt membranes. On one side, a tough polymer membrane, such as high-density polyethylene (HDPE) or TPO, offers excellent puncture, chemical, and aging resistance. On the other, a special non-asphalt-based self-adhesive layer acts like an invisible, strong tape, waiting for intimate contact with the concrete. Its clean edges, uniform width, and tightly wound rolls demonstrate the rigorous quality of industrial production. When laid on the foundation pit subgrade, its lightweight form and clean appearance create a transparent protective layer, not only preserving the surface without interfering with subsequent processes like rebar binding, but also blending effortlessly into the complex construction environment, showcasing the technological sophistication and professionalism of this modern building material.

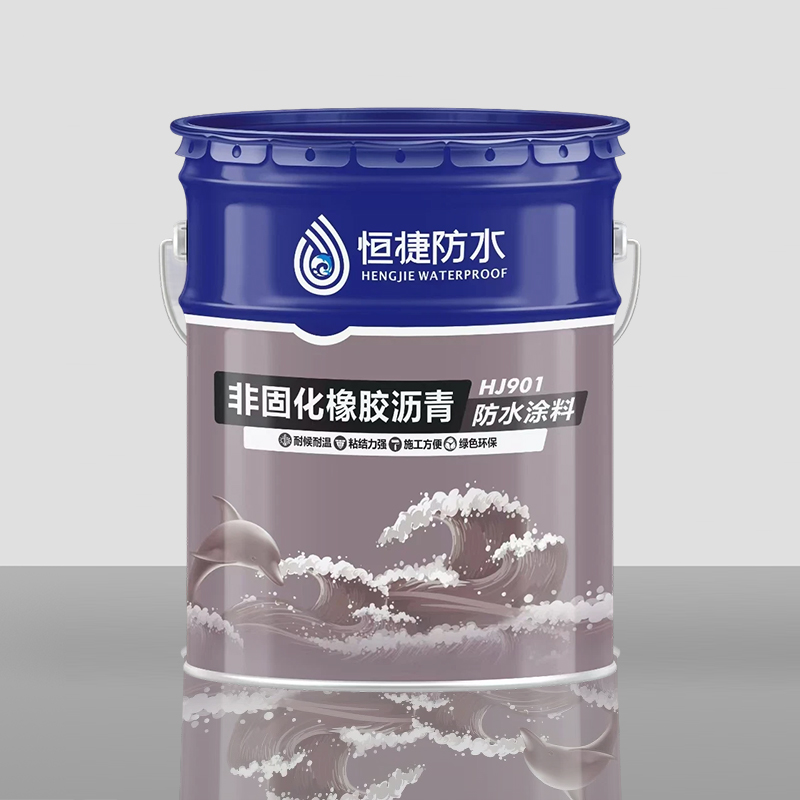

The core innovation lies in the intricate integration of non-asphalt-based self-adhesive adhesive and pre-laid reverse adhesive. Traditional waterproofing methods often rely on post-application, which can easily peel off on facades or leak through joints. Polymer self-adhesive film pre-laid waterproof membrane pioneers a pre-laid process: the membrane is laid bare on the subgrade, adhesive side facing up, before pouring the base slab concrete. When wet concrete is poured directly onto the membrane, the alkaline substances in the cement slurry undergo a unique chemical cross-linking reaction with the self-adhesive layer, forming an irreversible chemical bond that seamlessly integrates the membrane with the concrete structure, achieving a "skin-like" full adhesion. This "anti-adhesion" technology completely eliminates water leakage channels. Even if the membrane is partially damaged, water cannot penetrate beneath the waterproofing layer, truly achieving the ultimate goal of preventing water leakage. The NPS non-asphalt-based formula eschews traditional petroleum-based materials, making it environmentally friendly and non-toxic, offering superior high and low temperature resistance and preventing runaway or cracking. A specialized coating process ensures uniform thickness and stable activity of the self-adhesive layer, guaranteeing long-term, reliable adhesion.

From an application perspective, it forms the cornerstone of underground space safety. As a key waterproofing material, it is widely used in projects with extremely demanding waterproofing requirements, such as subways, tunnels, basements, and utility corridors. Its polymer-based membrane effectively resists groundwater penetration, soil acid and alkali erosion, and accidental damage from construction machinery. The pre-laying method simplifies the construction process, eliminating the need for a leveling layer or primer, making it suitable for damp surfaces and shortening construction time. Overlapping edges are hot-air welded or self-adhesive-sealed to form a continuous, seamless, integrated waterproof layer. Its excellent dimensional stability and tensile strength ensure it resists deformation and tearing even under complex stresses.

Polymer self-adhesive film pre-laid waterproof membrane is the "living membrane" at the foundation of a building. It binds concrete with chemical bonds and protects against the erosion of time with its polymeric armor. With every step of concrete solidification and rain wash, polymer self-adhesive film pre-laid waterproof membrane silently proves that true waterproofing lies not in the sheer stacking of materials, but in a deep understanding of bonding mechanisms and revolutionary innovations in construction methods. Polymer self-adhesive film pre-laid waterproof membrane provides protection before it's too late. Whether it's a deeply buried transportation hub or a lifeline beneath a city, polymer self-adhesive film pre-laid waterproof membrane, with its superior performance and reliable quality, has become an indispensable invisible shield in modern construction projects.

Upon first encounter with polymer self-adhesive film pre-laid waterproof membrane, its beauty stems from a "symbiosis of purity and precision." The membrane's surface is smooth and polished, exhibiting the characteristic uniform texture of polymer materials. Its color is pure, typically translucent or light, and it lacks the black stains and pungent odor often associated with asphalt membranes. On one side, a tough polymer membrane, such as high-density polyethylene (HDPE) or TPO, offers excellent puncture, chemical, and aging resistance. On the other, a special non-asphalt-based self-adhesive layer acts like an invisible, strong tape, waiting for intimate contact with the concrete. Its clean edges, uniform width, and tightly wound rolls demonstrate the rigorous quality of industrial production. When laid on the foundation pit subgrade, its lightweight form and clean appearance create a transparent protective layer, not only preserving the surface without interfering with subsequent processes like rebar binding, but also blending effortlessly into the complex construction environment, showcasing the technological sophistication and professionalism of this modern building material.

The core innovation lies in the intricate integration of non-asphalt-based self-adhesive adhesive and pre-laid reverse adhesive. Traditional waterproofing methods often rely on post-application, which can easily peel off on facades or leak through joints. Polymer self-adhesive film pre-laid waterproof membrane pioneers a pre-laid process: the membrane is laid bare on the subgrade, adhesive side facing up, before pouring the base slab concrete. When wet concrete is poured directly onto the membrane, the alkaline substances in the cement slurry undergo a unique chemical cross-linking reaction with the self-adhesive layer, forming an irreversible chemical bond that seamlessly integrates the membrane with the concrete structure, achieving a "skin-like" full adhesion. This "anti-adhesion" technology completely eliminates water leakage channels. Even if the membrane is partially damaged, water cannot penetrate beneath the waterproofing layer, truly achieving the ultimate goal of preventing water leakage. The NPS non-asphalt-based formula eschews traditional petroleum-based materials, making it environmentally friendly and non-toxic, offering superior high and low temperature resistance and preventing runaway or cracking. A specialized coating process ensures uniform thickness and stable activity of the self-adhesive layer, guaranteeing long-term, reliable adhesion.

From an application perspective, it forms the cornerstone of underground space safety. As a key waterproofing material, it is widely used in projects with extremely demanding waterproofing requirements, such as subways, tunnels, basements, and utility corridors. Its polymer-based membrane effectively resists groundwater penetration, soil acid and alkali erosion, and accidental damage from construction machinery. The pre-laying method simplifies the construction process, eliminating the need for a leveling layer or primer, making it suitable for damp surfaces and shortening construction time. Overlapping edges are hot-air welded or self-adhesive-sealed to form a continuous, seamless, integrated waterproof layer. Its excellent dimensional stability and tensile strength ensure it resists deformation and tearing even under complex stresses.

Polymer self-adhesive film pre-laid waterproof membrane is the "living membrane" at the foundation of a building. It binds concrete with chemical bonds and protects against the erosion of time with its polymeric armor. With every step of concrete solidification and rain wash, polymer self-adhesive film pre-laid waterproof membrane silently proves that true waterproofing lies not in the sheer stacking of materials, but in a deep understanding of bonding mechanisms and revolutionary innovations in construction methods. Polymer self-adhesive film pre-laid waterproof membrane provides protection before it's too late. Whether it's a deeply buried transportation hub or a lifeline beneath a city, polymer self-adhesive film pre-laid waterproof membrane, with its superior performance and reliable quality, has become an indispensable invisible shield in modern construction projects.